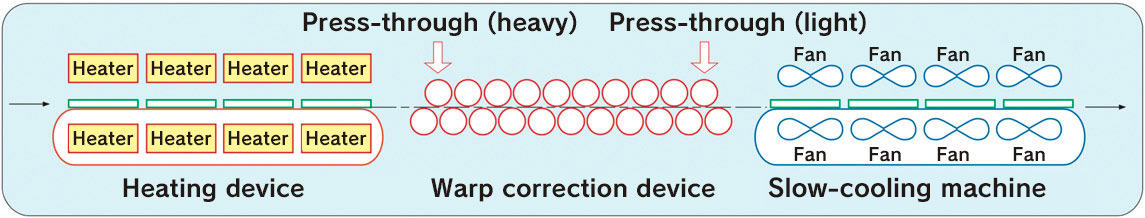

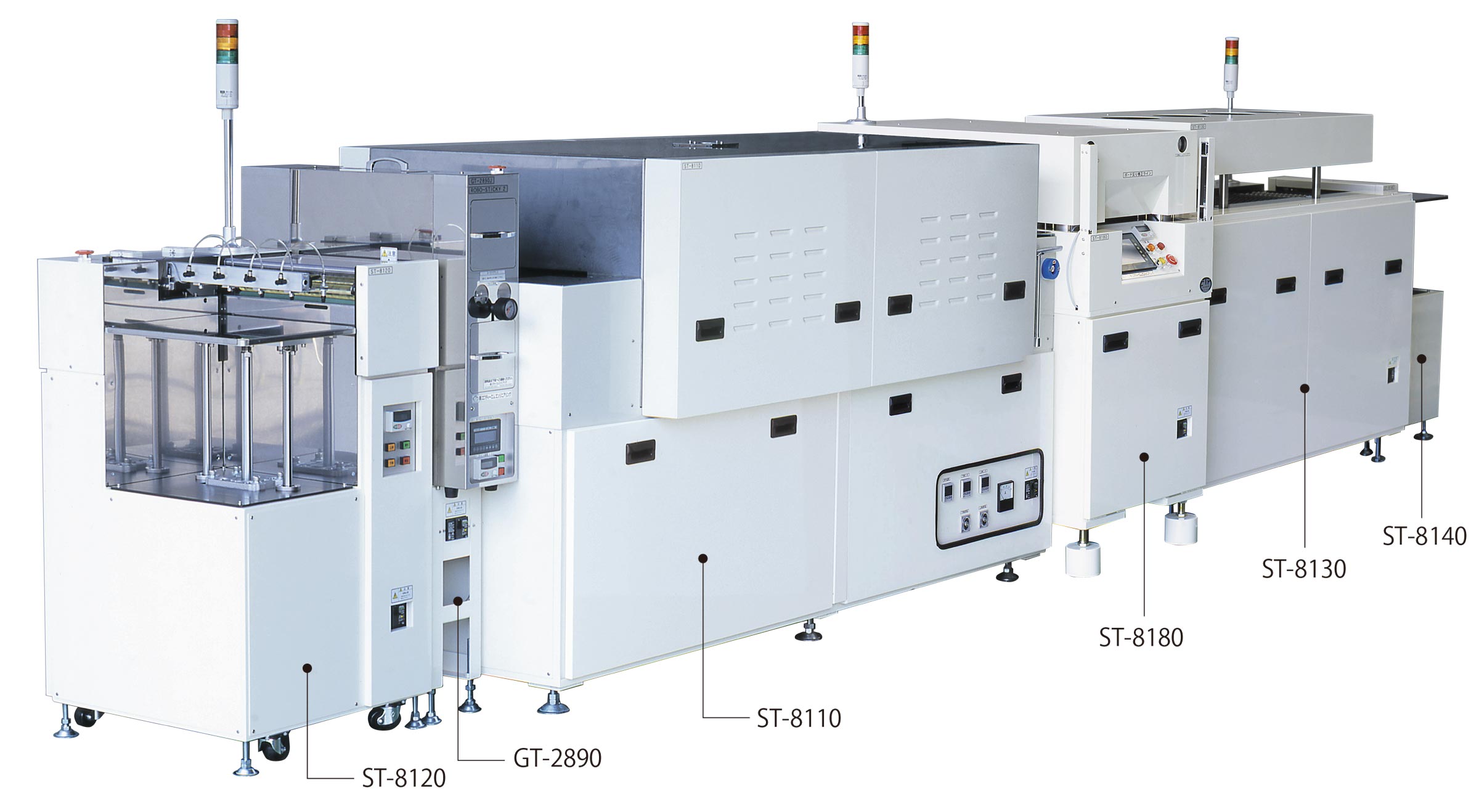

Our highly-rated “Printed Circuit Board Warp Correction System” is realized though the combination of a heating device, warp correction device, and a slow-cooling machine that incorporates our company’s know-how into a single system.

Printed circuit board warp correction system

Workpiece Specifications

A printed circuit board warp inspection and judgment system that intakes board, measures board warping, and then differentiates between passing and failing products.

![Warp Inspector [Auto-Judgment Type]](images/ftm_warpreform/ftm_warpreform04_pc.jpg)

Workpiece Specifications

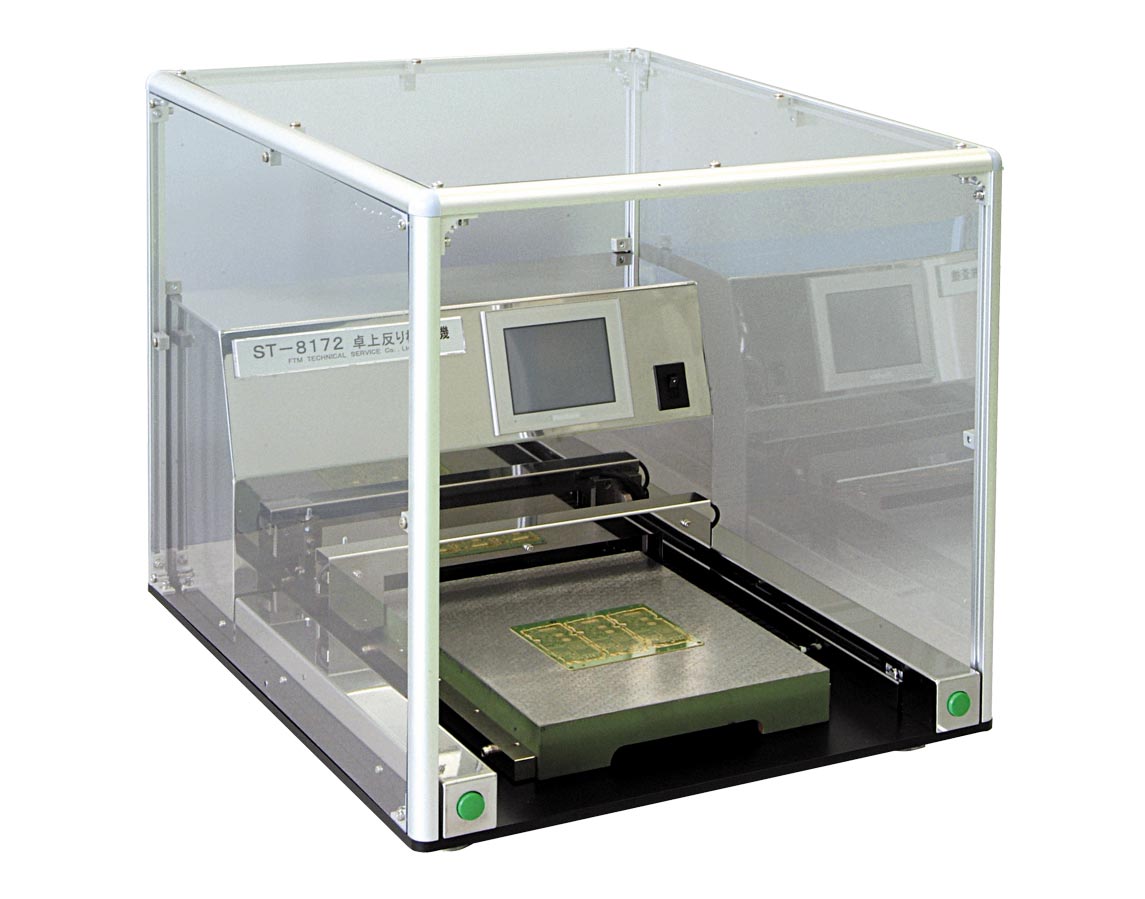

This desktop board warp inspector allows you to easily inspect board warping by just placing a board on the device’s table and pressing a switch.

Specifications

● Machine dimensions: Approx. (W) 600 x (D) 680 x (H) 600 mm